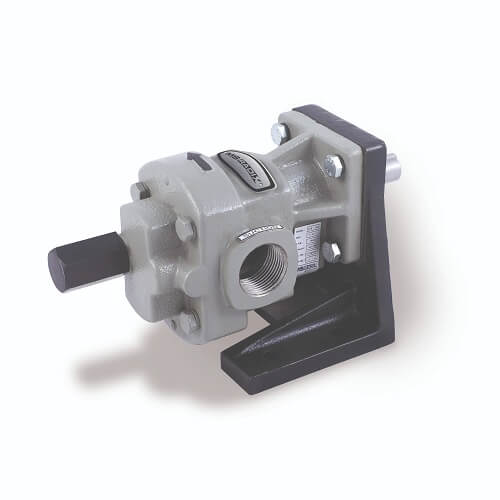

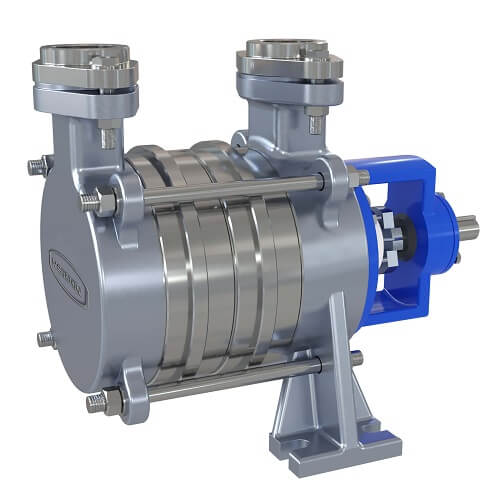

MSRN/RB/RX Series Rotary Gear Pump

MSRADIX® MSRN/MSRB/MSRX pumps have a three-piece construction & can be easily cleanable and maintainable. These pumps have an increased life & performance as the double helical gear prevents axial load & side thrust. These pumps are suitable for use with liquids with a maximum temperature of 200oC & viscosity of 100000 SSU.

Heavy duty foot mounting type gear pump designed for continuous application.

Suction size from ½” to 6”with flange (class 150 # ASME/ANSI B 16.5).

Capacity: 25LPM to 2080LPM.

Maximum working pressure: 10bar.

Maximum working temperature: 300oc.

Maximum viscosity: 25000 CST.

Herringbone rotor design eliminate side thrust.

Modified tooth profile enhance tooth life.

Jacking construction available.

Double helical gear design prevent axial load.

Low leakage path by design improve volumetric efficiency.

Shorter bearing span reduces bending effect.

Application Industry

Oil & gas industry

Steel plant

Paint, varnish & ink industry

Sugar industry

Pharma industry

Chemical industry

Model Selection

MSRB/MSRN: For clean viscous liquid having sufficient values such as vegetable oil, animal oil, fish oil, clean tube oil, gear oil, hydraulic oil, glycerin, automotive & diesel engine oils etc. for intermitted duty, the bush bearing type of pump (MSRB) is used and for continuous duty, needle roller bearing type of pump (MSRN) is selected.

MSRX: For liquid having low viscosity, low lubricating values, impure/dirty crude oil, dirty lube oil, HSD, kerosene, sugar solutions, LDO paints, wood pulp, varnish, turpentine etc.

MSRBJ: The pump with the jacketing construction is for liquid which tends to solidify at room temperature such as bitumen/asphalt/tar, furnace oil, starch, molasses, naptha, soap solution, wax etc. The jacketing construction in the pump facilities heating of the pump by steam or thermic fluid.

Model & Performance Chart

Pump Model (Suction & Delivery) MSRN/MSRB/MSRX | Capacity at 1440RPM | Recommended Motor HP at 1440RPM for Pressure | |||||

LPM | US GPM | m3/hr | 0 to 3 kg/cm2 | > 3 to 7 kg/cm2 | > 7 to 10 kg/cm2 | ||

50 ½” x ½” | S | 10 | 2.64 | 0.60 |

0.50

|

0.75

|

1.00

|

M | 15 | 3.96 | 0.90 | ||||

L | 25 | 6.60 | 1.50 | ||||

100 1” x 1” | S | 30 | 7.92 | 1.80 |

1.00

|

1.50

|

2.00

|

M | 50 | 13.20 | 3.00 | ||||

L | 60 | 15.85 | 3.60 | ||||

150 1½” x 1½” | S | 80 | 21.13 | 4.80 |

2.00

|

3.00

|

5.00

|

M | 100 | 26.41 | 6.00 | ||||

L | 125 | 33.02 | 7.50 | ||||

200 2” x 2” | S | 150 | 39.62 | 9.00 |

3.00

|

5.00

|

7.50

|

M | 165 | 43.58 | 9.90 | ||||

L | 200 | 52.83 | 12.00 | ||||

250 2½” x 2½” | S | 250 | 66.04 | 15.00 |

5.00

|

7.50

|

10.00

|

M | 300 | 79.25 | 18.00 | ||||

L | 330 | 87.17 | 19.80 | ||||

300 3” x 3” | S | 415 | 109.63 | 24.90 |

10.00

|

12.50

|

15.00

|

M | 450 | 118.87 | 27.00 | ||||

L | 500 | 132.08 | 30.00 | ||||

400 4” x 4” | S | 600 | 158.50 | 36.00 |

15.00

|

20.00

|

25.00

|

M | 665 | 175.67 | 39.90 | ||||

L | 830 | 219.26 | 49.80 | ||||

500 5” x 5” | S | 1000 | 264.17 | 60.00 |

20.00

|

30.00

|

40.00

|

M | 1250 | 330.21 | 75.00 | ||||

L | 1500 | 396.25 | 90.00 | ||||

600 6” x 6” | S | 1650 | 435.88 | 99.00 |

30.00

|

50.00

|

60.00

|

M | 1825 | 482.11 | 109.50 | ||||

L | 2080 | 549.47 | 124.80 | ||||

Material of Construction

| Parts | Material for MSRN/MSRX | Material for MSRB |

| Pump Body | CI / CS | CI / CS |

| Front Cover | CI / CS | CI / CS |

| Back Cover | CI / CS | CI / CS |

| Gland Cover | CI / CS | CI / CS |

| Rotor / Stator Shaft | EN-19 | EN-19 |

| Gear | EN-24 / 353 | EN-24 / 353 |

| Needle / Bush Bearing | INA / IKO (Japan) | Non – Ferrous |

| Wear Plate | Bronze | Bronze |

| R.V. Housing | Mild Steel | Mild Steel |

| R.V. Piston | EN – 8 | EN – 8 |

| R.V. AD Screw | EN – 8 | EN – 8 |

| Sealing | Neoprene Oil Seal | Gland Packing |